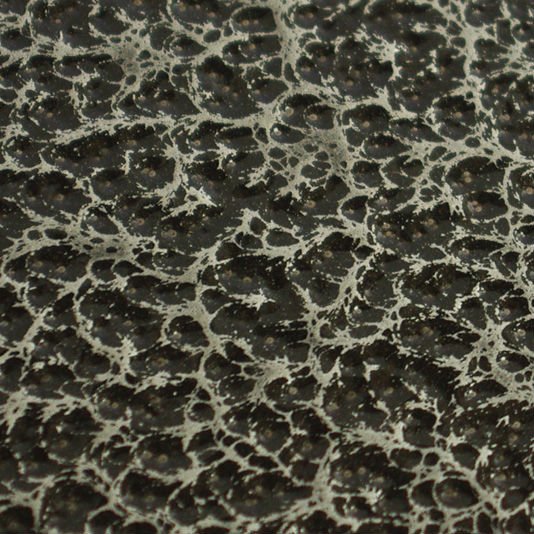

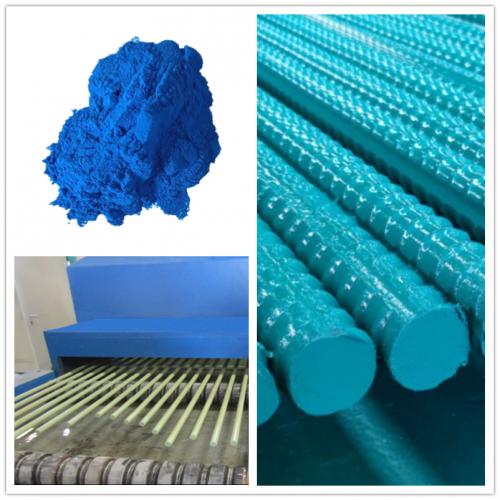

Exterior cooper vein powder coating paint

- Product Item : 00026

- Category: Antique powder coating

- antique

- thermosetting

- electrostatic

- outdoor

- Product description:Pure polyester powder coating with tgic is most common kind of powder used for both indoor and outdoor. It has good quantity for weather resistanct, anti-yellowing, corrorrion resiatant.

Exterior cooper vein powder coating paint

polyester powder coating based on saturated polyester resins specially selected for exterior use. It is formulated to give properties of good flow-out and satin or glossy finish. Its outstanding resistance to ultra-violet light and atmospheric aging make it highly decorative and durable in outdoor environment,It is widely used for outdoor furniture,architectural hardware,air-conditioners,bicycle frames,garage doors and signboards etc .

|

Main Material |

Polyester resin,barium sulfate,titanium dioxide |

|

Surface Type |

Gloss,matte,wrinkle,sand grain,antique, Hammer,crocodile skin, wood effect,candy,chrome, transparent,semitransparent,metallic,and special pattern |

|

Powder Properties |

Specific gravity : 1.3 - 1.75 (depend on colors) |

|

Average particle size : 35 - 45um |

|

|

Coating Properties |

Film thickness(ISO 2178) :60 - 90 μm |

|

Coverage:15 square based on 60μm |

|

|

Pencil hardness: ASTM D3363,H-2H |

|

|

Adhesion :GB/T 9286-1998,0 grade |

|

|

Bending test:GB/T 6742 ,=<2mm |

|

|

Cupping test:GB/T 9753,>=7mm |

|

|

Direct and reverse impact (ASTM D2794) : > 50kg.cm |

|

|

Salt spray Resistance ( ASTM B117, 1000hrs)(Maximum undercutting ,1 mm ): No blistering or loss of adhesion |

|

|

Heat and moisture test GB/T 1740,>=1000 hours,no change |

|

|

Application Schedule |

Applied by : Electrostatic spraying devices |

|

Curing schedule :10 minutes at 200 ℃ |

|

|

Advantage |

Good adhesion,anti-corrosion,UV resistant, strong coating film, |

|

Accurate colors, good leveling |

|

|

Shelf Life |

12 months |

INQUIRY

CATEGORIES

- Epoxy Powder Coating

- Epoxy Polyester Powder Coating

- Polyester Powder Coating

- Metallic Finish Powder Coating

- Ral color powder coatings

- Wrinkle powder coating

- Antique powder coating

- Sand texture powder coating

- Crackle Powder Coating

- Candy Powder Coating

- High temperature resistant powder

- Heat transfer printing powder coating

- Thermoplastic(PE)powder coating

- Anti-static powder coating

- Powder coating line

LATEST NEWS

CONTACT US

Name: Kim Lau

Mobile:+86 15651959913

Tel:+86 15651959913

Whatsapp:8615651959913

Email:sales@odaipowdercoating.com

Add:Feichuan Industrial Zone, Huagang Town, Hailing District,Taizhou 225517, Jiangsu