About us

Jiangsu Odai New Material Co., Ltd is specialized in the powder coating manufacturing industry since the year 2010. Besides the Chinese market, we also put a lot of effort into international business and have already exported to a lot of countries like Mexico, Peru, Chile, USA, Saudi Arabia, Yemen, Iraq, UAE, South Africa, UK, South Korea, Malaysia, and Indonesia. Pakistan, Russia, Uzbekistan ect total more than 40 countries till the year 2023. The products win good reputation in the world. The advantageous products of our company are Metallic Powder Coating and Anti-static powder coating. We can make them with superior quantity and attractive price. Surely for the common powder like Epoxy powder coating, polyester powder coating, and Epoxy polyester powder coating in Ral colors, Pantone colors, and textured finish, we can give a satisfactory completion in our daily production. Our factory is located in Taizhou, Jiangsu which is near the Changjiang River and very close to Shanghai. Welcome to choose us as a lifetime partner. We are honored to communicate with you about everything related to powder coatings.

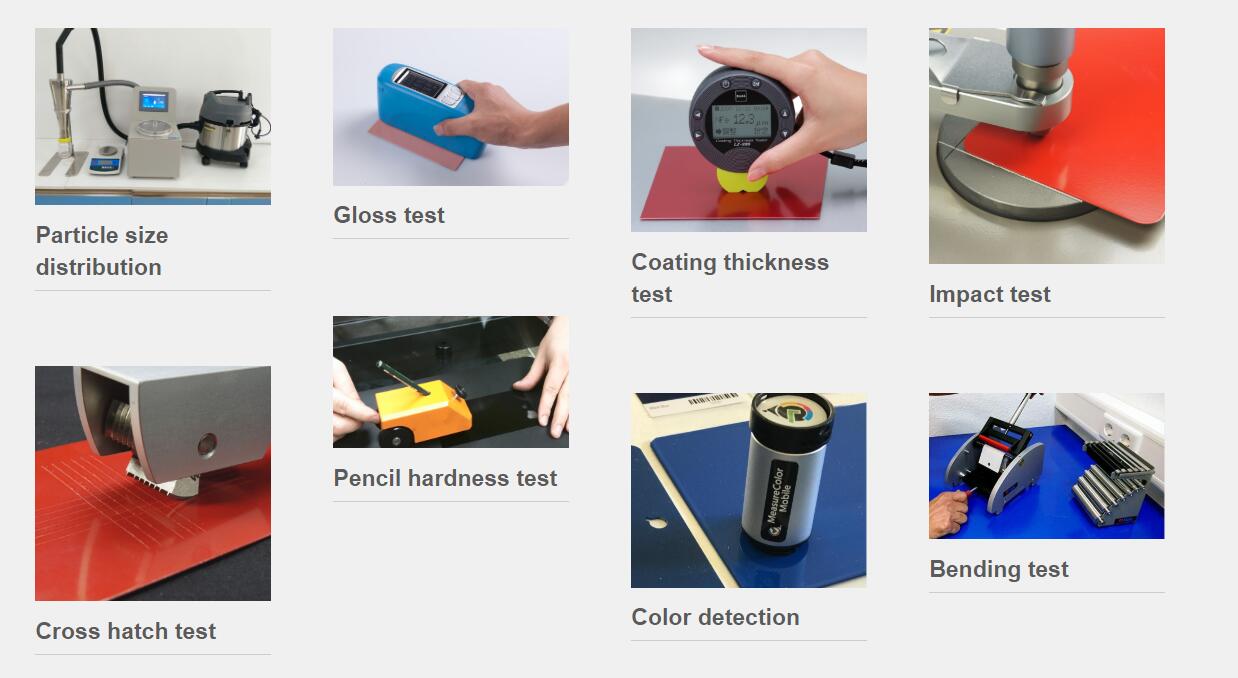

POWDER COATING TEST METHODS

(1) SALT SPRAY CORROSION TEST (ASTM B117)Use a 5% salt solution at 92-97 degrees F in a sealed weather cabinet. Scribe X in steel zinc phosphated test panel to bare metal. Inspect every 24 hours. End test and total hours after 1/4″ creepage from scribed area. Creepage shall not exceed 1/4″ in either direction from scribe line after 500 hours exposure.(2) IMPACT TEST (ASTM D2794)Coating on .036 inch thick phosphated steel panel shall withstand impact with 1/2″ Gardener impact tester ball at 26 inch pounds direct and reverse. No grazing or loss of adhesion. Finish shall not be able to be removed at impact area with tape.

(3) CHEMICAL RESISTANCE TEST (ASTM D1308)Place approximately 10 drops of test solvent, consisting of 95% by weight toluene and 5% by weight Methal Ethyl Keytone on the surface of the coating. Allow to stand for 30 seconds. Wipe off with soft, dry cloth. Coating shall show no more than a slight circular mark.

(4) CROSS HATCH ADHESION TEST (ASTM D3359)Scribe parallel lines through coating to substrate, 1/4″ apart over a distance of one inch. Scribe another set of parallel lines 1/4″ apart and perpendicular to the first set. Apply any sticky tape then remove slowly. Results should be no lifting of the cured powder between scribe lines.

(5) HARDNESS TEST (ASTM D3363)Faber Castell wood pencils are used in hardness of 1,2,3,4,. Coating shall show no marks from 2H pencil.

(6) BEND TEST (ASTM D522)Coating on .036 inch thick phosphated steel panel shall withstand 180 degree bend over 1/4″ mandrel. No crazing or loss of adhesion and finish at the bend be able to be removed with tape.

(7) GLOSS TEST (ASTM D523)

Test coated flat panel with Gardener 60 degree meter. Coating shall not vary + or – 5% from data sheet requirements on each material supplied.

CATEGORIES

- Epoxy Powder Coating

- Epoxy Polyester Powder Coating

- Polyester Powder Coating

- Metallic Finish Powder Coating

- Ral color powder coatings

- Wrinkle powder coating

- Antique powder coating

- Sand texture powder coating

- Crackle Powder Coating

- Candy Powder Coating

- High temperature resistant powder

- Heat transfer printing powder coating

- Thermoplastic(PE)powder coating

- Anti-static powder coating

- Powder coating line

LATEST NEWS

CONTACT US

Name: Kim Lau

Mobile:+86 15651959913

Tel:+86 15651959913

Whatsapp:8615651959913

Email:sales@odaipowdercoating.com

Add:Feichuan Industrial Zone, Huagang Town, Hailing District,Taizhou 225517, Jiangsu