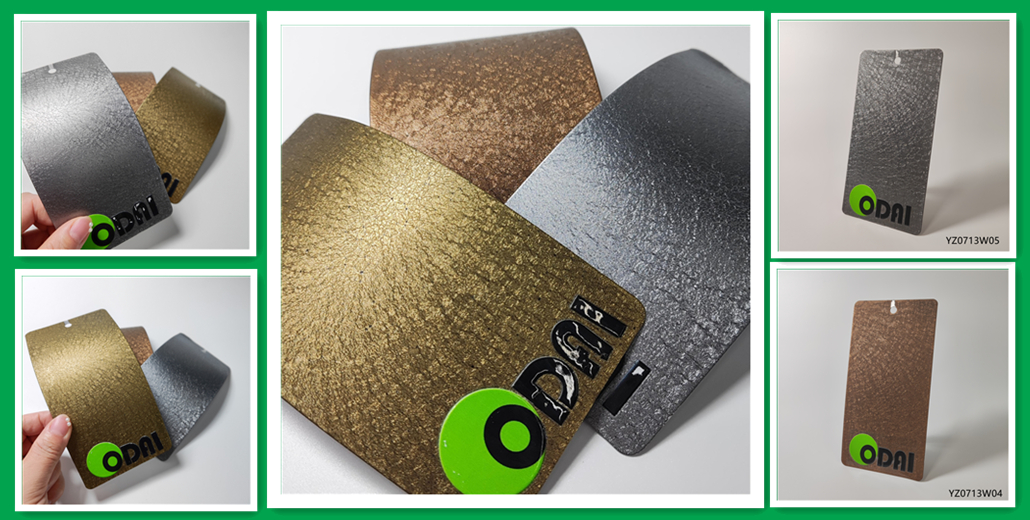

Epoxy powder coating light brown colored with texure

- Product Item : 00029

- Category: Crackle Powder Coating

- indoor

- hybrid

- thermosetting

- electrostatic

- Product description:Epoxy powder coating,chinese powder coating manufacturer,Odai powder coating,light brown powder coating,texured powder coating

Epoxy powder coating light brown colored with texure

The purpose of formulating this powder coating is to achieve a high gloss smooth coating with excellent adhesion, bending and chemical resistance. The main disadvantage is that it is easy to yellow at high temperatures or after exposure to sunlight. In addition, this coating will quickly pulverize when exposed to outdoor exposure. However, the integrity of the film under outdoor exposure is very good. The curing of epoxy powder coatings is additive curing and does not release volatiles during drying.

|

Main Material |

Epoxy resin,barium sulfate,titanium dioxide |

|

Surface Type |

Gloss,matte,wrinkle,sand grain,antique, Hammer,crocodile skin, wood effect,candy,chrome, transparent,semitransparent,metallic,and special pattern |

|

Powder Properties |

Specific gravity : 1.3 - 1.75 (depend on colors) |

|

Average particle size : 35 - 45um |

|

|

Coating Properties |

Film thickness(ISO 2178) :60 - 90 μm |

|

Coverage:15 square based on 60μm |

|

|

Pencil hardness: ASTM D3363,>HB |

|

|

Adhesion :GB/T 9286-1998,0 grade |

|

|

Bending test:GB/T 6742 ,=<2mm |

|

|

Cupping test:GB/T 9753,>=7mm |

|

|

Direct and reverse impact (ASTM D2794) : > 50kg.cm |

|

|

Salt spray Resistance ( ASTM B117, 200hrs)(Maximum undercutting ,1 mm ): No blistering or loss of adhesion |

|

|

Heat and moisture test GB/T 1740,>=500 hours,no change |

|

|

Application Schedule |

Applied by : Electrostatic spraying devices |

|

Curing schedule :15 minutes at 180 ℃ |

|

|

Advantage |

Good adhesion,extremly hardness strong coating film, |

|

Accurate colors, good leveling |

|

|

Shelf Life |

12 months |

INQUIRY

CATEGORIES

- Epoxy Powder Coating

- Epoxy Polyester Powder Coating

- Polyester Powder Coating

- Metallic Finish Powder Coating

- Ral color powder coatings

- Wrinkle powder coating

- Antique powder coating

- Sand texture powder coating

- Crackle Powder Coating

- Candy Powder Coating

- High temperature resistant powder

- Heat transfer printing powder coating

- Thermoplastic(PE)powder coating

- Anti-static powder coating

- Powder coating line

LATEST NEWS

CONTACT US

Name: Kim Lau

Mobile:+86 15651959913

Tel:+86 15651959913

Whatsapp:8615651959913

Email:sales@odaipowdercoating.com

Add:Feichuan Industrial Zone, Huagang Town, Hailing District,Taizhou 225517, Jiangsu